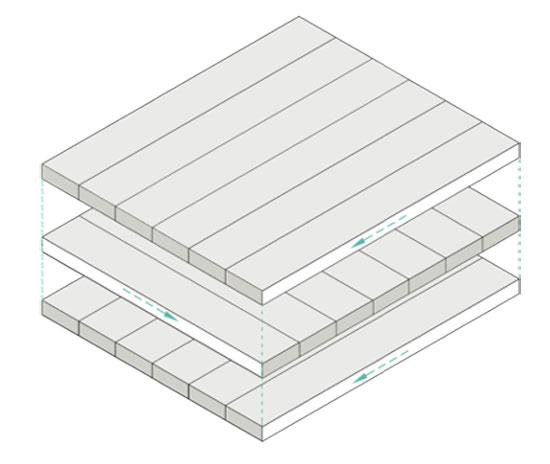

CLT, or cross-laminated timber, is a structural material for construction manufactured in the form of panels composed of several layers of glued sawn timber boards placed perpendicularly on top of each other. (The minimum number of layers is 3).

Structurally classified sawn timber boards are used for its production.

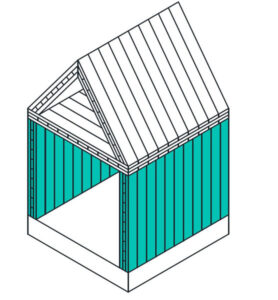

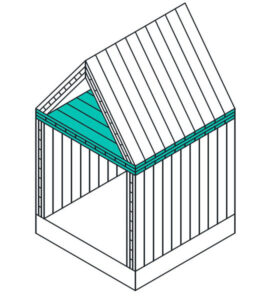

CLT panels can be used as structural elements such as walls, floors or roofs.

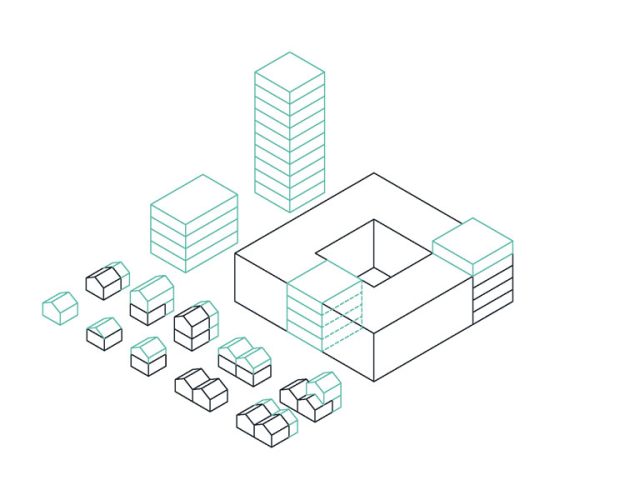

CLT PROJECT TYPES

With CLT, we can create the structure of any building type. Thanks to its technical characteristics, it can be used in both small and medium- and high-rise buildings.

There are many advantages to using CLT as a construction material. These include:

- Óptimal strength-to-weight ratio.

A structure with the same strength but a lower weight, allowing for optimized foundations. Lower foundation costs.

Its lightness makes it easier to handle on-site compared to other systems.

Very useful for extensions to existing buildings, as it adds less weight than other systems.

- Higher degree of industrialization and precision

Thanks to CNC or numerical control machines, once manufactured, CLT panels are machined to the specific shape and exact dimensions of the project, allowing for greater precision and a lower risk of on-site failures.

It requires greater definition in the design phase, as the panels will leave the factory with a high level of construction precision, ready for direct installation on-site.

- Dry construction and faster assembly.

Waiting times on-site are reduced (there is no need to wait for setting or curing times for the structure to be loaded).

Quick and easy assembly and joining.

Reduced construction time = lower costs.

Cleaner construction, lower expenditure of resources such as water, and less waste generation.

- Reduced carbon footprint if produced locally.

Circular, renewable, and recyclable.

Wood is a material that achieves a negative carbon footprint at the end of its life cycle.

A construction system that is more respectful of the environment and the immediate surroundings.

Minimal waste reduction.

As a construction element, it continues to store CO2 throughout its entire lifespan.

- Good energy performance.

Construction with CLT greatly facilitates the elimination of thermal bridges in the thermal envelope.

Relatively low thermal conductivity, functioning as both a structure and an enclosure.

Without being an insulating material, wood provides a much higher level of insulation than other materials, which allows for reduced thicknesses of enclosures, achieving greater usable surface area, with equal thermal requirements.

- Architectural aesthetics and warmth.

Great aesthetic possibilities.

Possibility of leaving it “exposed” by relying on the aesthetics and warmth of the wood itself, or it can be covered with other materials to achieve other types of visual effects.

These are some of the steps in the production of our CLT panels:

The Xilonor panel range consists of the following products:

| CLT Designation | Layer | Resistance class of the boarding according to EN 338 |

| Xilo-CLT | Outer layers | 100% C16 |

| Inner layers | 100% C16 | |

| Xilo-CLT+ | Outer layers | 100% C24 |

| Inner layers | ≥ 70% C16 ≤ 30% C24 |

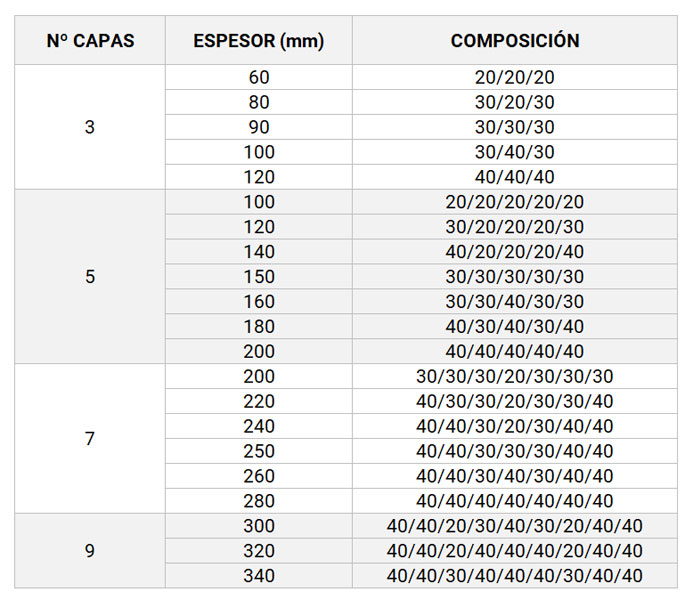

The layer composition is typically a symmetrical section consisting of 3, 5, 7, or 9 layers.

*Other compositions are available upon request, depending on table availability.

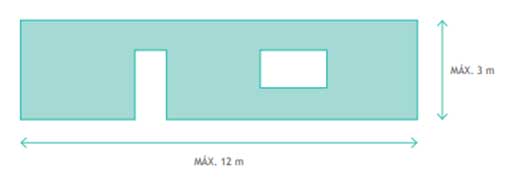

Our maximum production sizes are up to 3.00m x 12.00m.

Xilo-CLT and Xilo-CLT+ panels can be manufactured so that their external layers present different possibilities of surface visual finish:

N Non Visual Quality Panels that will be clad. The CLT will not be visible.

I Medium Visual Quality* Panels that will be exposed with intermediate aesthetic requirements, e.g., commercial or industrial buildings.

V High Visual Quality* Panels that will be exposed and require high aesthetic demands, e.g., residential buildings, schools, and offices.

*Medium and high visual qualities include surface sanding.

QUALITIES CLT XILONOR | ||||||

Denomination | NN | VN | VV | IN | II | VI |

Outer Layer | N | V | V | I | I | V |

Inner Layer | N | N | N | N | N | N |

Outer Layer | N | N | V | N | I | I |

Organization and logistics are two of the key aspects for maximizing project time and costs in a CLT project.

Once all the parts for a project are machined in our factory to the final shape and dimensions, the load is prepared for transport, taking into account the type of transport required (*consult options with the technical office), ensuring that the loading sequence established by the client is followed. (This sequence may be modified for reasons of truck and load stability.) Once loaded, the load will be delivered to the address provided by the client (accessible for trailers) within our delivery capabilities (*consult options with the technical office).